Blog

The Importance of Watering a Forklift Battery

Forklifts are an essential piece of machinery for various sectors, including manufacturing and warehousing. In order to keep running and functioning properly, it's important they have routine maintenance. An example of this is ensuring things like the battery are hydrated appropriately.

This blog will take a deep dive into the specifics of what is needed in order to keep your forklift battery hydrated including a step-by-step tutorial of how to do it.

Why Watering Your Forklift Battery Is Important

Lead-acid batteries, which run on a sulphuric acid and water mixture, are regularly used in forklift batteries. Due to preserving the electrolyte levels within the battery, this makes the water component essential. As a result of the water in the battery evaporating during discharge, the electrolyte level falls. The water levels could potentially drop too low, and if this is the case, then the battery can potentially be exposed to air. This will shorten the battery’s lifespan and cause irreversible damage, which could lead to some expensive repairs and replacements.

Here are some key reasons why watering forklift batteries is essential for keeping your battery healthy:

Prolongs Battery Life

Watering the battery regularly will stop the lead plates from drying out, and as a result of this, it will help the battery last as long as possible.

Maintains Optimal Performance

If a battery is well maintained, it will hold a charge a lot better and longer, which will deliver a more consistent power supply to your forklift. This will ensure a smooth operation for more time.

Prevents Costly Repairs

If battery maintenance is not prioritised, when necessary, it can lead to expensive repairs or, worse case, a brand-new battery being needed.

Watering Your Forklift Battery

What You’ll Need to Water Your Forklift Battery

Before you start the process, it's essential to gather the necessary materials. Here’s what you’ll need:

- Distilled Water: When maintaining your battery, make sure to use distilled water. The reason for this is because tap water contains minerals and impurities that can damage the battery over a long enough time frame.

- Personal Protective Equipment (PPE): safety equipment including safety goggles, gloves, and protective clothing is essential when working with batteries to make sure you are protected from acid splashes.

- Battery Watering Gun or Bottle: A specialised battery watering gun or bottle will make sure you get the correct amount of water to the battery, which will keep it functioning correctly.

- Flashlight: A very useful piece of equipment to help make sure the water levels are precise.

Step-by-Step Guide to Watering Your Forklift Battery

Now you have the correct equipment, lets go through a step-by-step process of how to properly water your forklift battery:

- Prioritise safety: First things first, make sure the battery is turned off so that the battery isn’t hot. Make sure you are wearing PPE equipment to ensure you are not at risk of any potential hazards taking place.

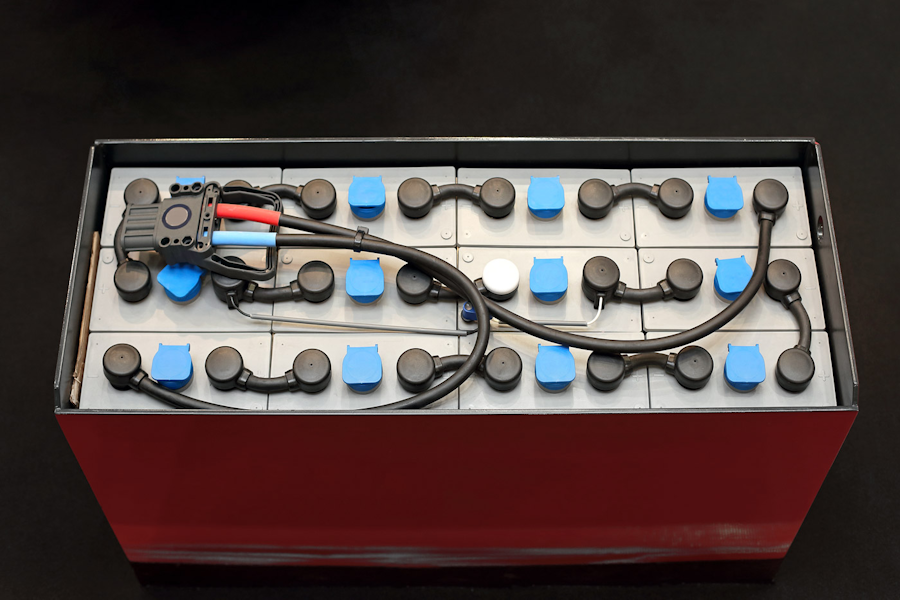

- Find where the battery cells are located: Find where the battery compartment of the forklift is and carefully open it up. When you open the battery compartment, you will see multiple battery cells, all of which will have their own cap. After taking the caps off, you will see an entrance in which the water can be added through.

- Making sure the water level is correct: Take each cap off one at a time. Once you have done this, use your flashlight to check the water level of each cell. The lead plates should be covered by the water, although make sure it is not too full. The perfect level is just below the fill tube inside each cell.

- Add Distilled Water: If the water level is too low when you take the caps off, carefully fill each one up to the correct water level. Use a battery watering gun or bottle to avoid overfilling and to decrease the chances of spillage. Add just enough water to bring the level to the appropriate height. Overfilling needs to be avoided as it can lead to the battery having issues when charging, one of which is acid spillage.

- Secure the Caps: Once all the cells have been checked and topped up, securely replace the caps on each cell.

- Charge the Battery: It’s best to water the battery after it has been fully charged because the water level rises during charging. Charging the battery before watering the cells helps ensure that you are not adding too much and therefore helps it stop from overfilling.

- Clean Up: If you notice any spills, make sure you clean them up using a damp cloth. Once you are done with the cloth, also ensure you dispose of this correctly, as battery acid can be negatively impactful to the environment.

- Regular Maintenance: Try and set a schedule for when you check your forklift battery and if it needs watering. The time between checking the battery will be different for everyone due to the usage time having an effect on how quickly it needs to be watered. On usage, this could be weekly or monthly. Always follow the manufacturer’s recommendations when possible.

Tips for Effective Forklift Battery Maintenance

- Keep a Schedule: By keeping you informed about watering and other important duties; regular planned maintenance can help you keep your forklift battery operating at its best.

- Monitor Battery Health: Pay attention to additional indicators of battery health, such as physical condition and charge retention, in addition to moisture. Larger problems in the future can be avoided by detecting problems early.

- Purchase a Watering System: If you oversee a fleet of forklifts, you might want to think about purchasing a battery-operated, automated watering system. Time can be saved, and there is a lower chance of human error.

In need of more information about forklift batteries?

If you have any further questions about watering forklift batteries or are in need of more information about forklift batteries in general, PHL’s team of experts are happy to help. Contact us today.

Subscribe

Keep up to date with PHL and all things forklift machinery.